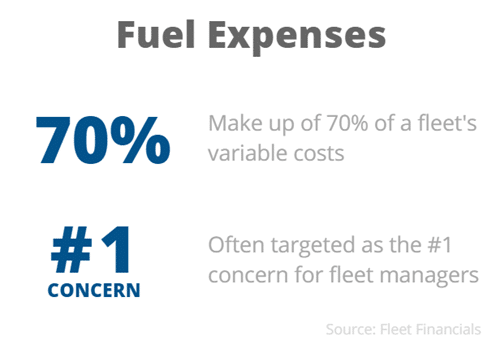

Fuel costs are a major concern for the fleet industry, often constituting the largest portion of operating expenses. Fluctuating fuel prices, influenced by global events and market dynamics, add a significant level of unpredictability to budgeting and operational planning for fleet businesses. In the context of rising fuel prices post-pandemic and geopolitical events such as the conflict in Ukraine, managing and reducing fuel consumption has become a top priority for companies to maintain profitability and competitive edge.

Telematics is a transformative technology for fleet management, involving the integration of telecommunications and informatics. It encompasses GPS tracking, vehicle diagnostics, and real-time data communication to enhance vehicle performance, driver safety, and overall operational efficiency. By providing insights into vehicle location, driver behavior, and vehicle activity, telematics enables fleet managers to make informed decisions, improving the efficiency and productivity of fleet operations. Moreover, fleets can leverage the power of telematics to save on fuel costs and positively impact their bottom line.

The purpose of this article is to explore how telematics technology can be a pivotal tool for fleet managers looking to mitigate the impact of high fuel costs. We will delve into the various functionalities of telematics that contribute to fuel savings, from optimizing routes to improving driver behaviors.

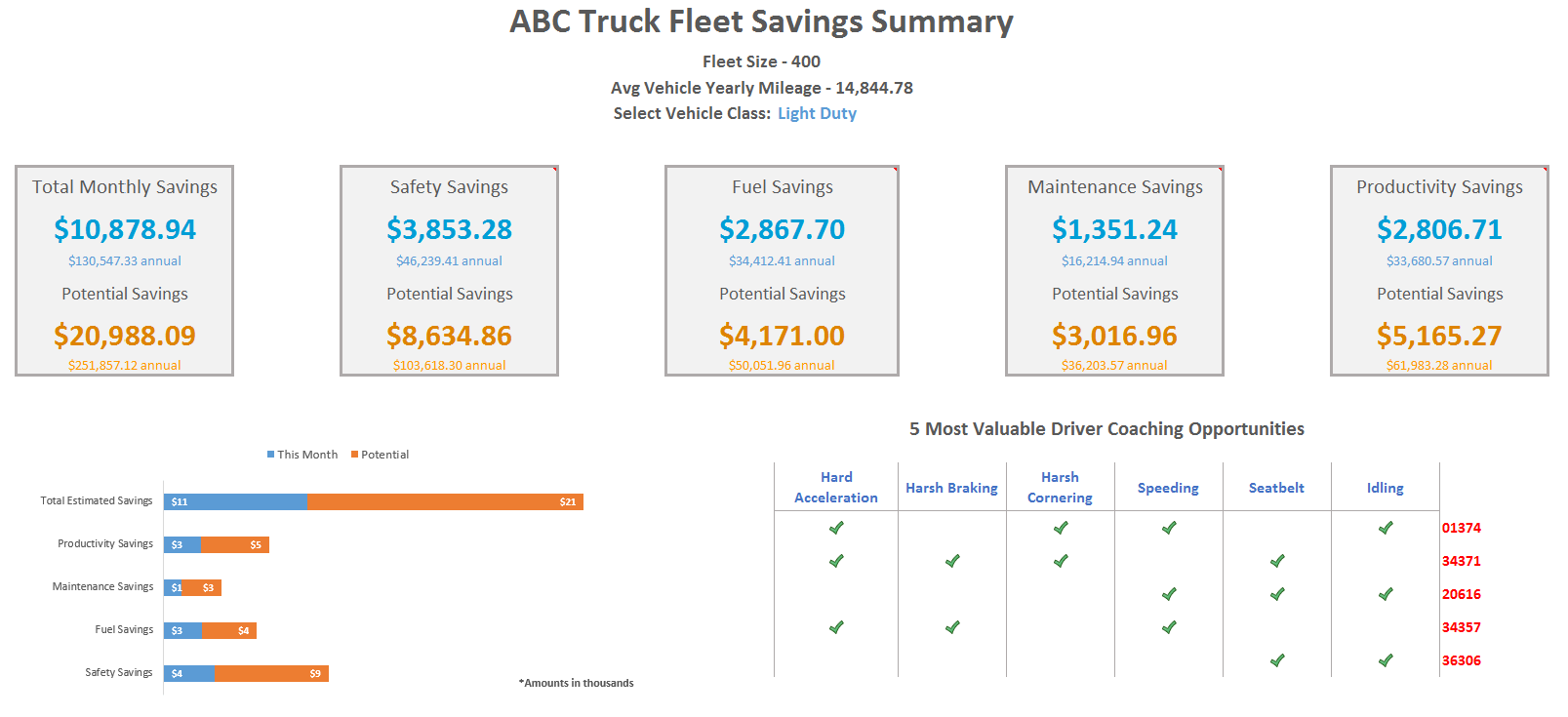

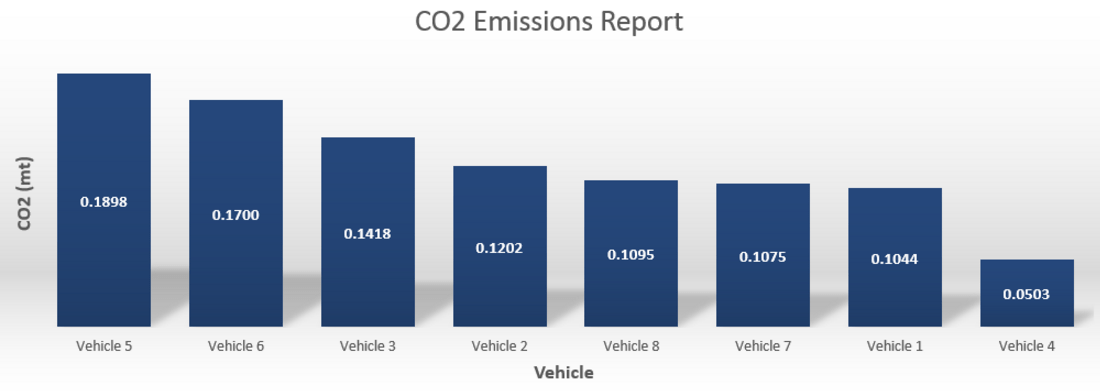

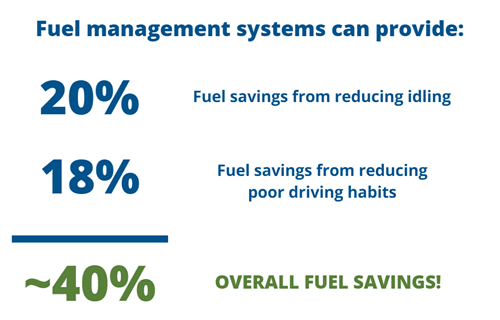

By leveraging telematics, fleets can potentially achieve up to a 25% decrease in fuel costs, which not only enhances economic efficiency but also contributes to environmental sustainability by reducing carbon emissions. Furthermore, with transportation being a significant contributor to greenhouse gas emissions globally, adopting telematics offers a dual benefit of cost savings and reduced environmental impact.

In the following sections, we will discuss the specifics of how telematics can lead to these benefits, backed by real-world statistics and case studies, providing a comprehensive understanding of its role in fuel cost reduction and efficient fleet management.

Understanding Telematics

Telematics technology is an interdisciplinary field that encompasses telecommunications, vehicular technologies, road transportation, road safety, electrical engineering (sensors, instrumentation, wireless communications, etc.), and computer science. It involves the transmission of information over long distances. In the context of fleet management, telematics refers to the integrated use of telecommunications and informatics for sending, receiving, and storing information related to remote objects, like vehicles, through telecommunication devices.

Key Components of a Telematics System

The key components of a telematics system often include:

- GPS Device: To pinpoint the exact location of the vehicle.

- Onboard Diagnostics (OBD) II Port: Collects data from the vehicle’s internal computer.

- Telematics Control Unit (TCU): Processes and transmits vehicle data.

- Telecommunications Network: Enables the transmission of data between the vehicle and the central management system.

- Data Storage: A cloud or server-based storage system to keep the collected data secure and accessible.

- User Interface: Software platforms that present data to the end-user in a comprehensible format, often through dashboards, reports, and real-time alerts.

The Role of Telematics in Vehicle Tracking and Diagnostics

Vehicle Tracking: Telematics plays a critical role in vehicle tracking by using GPS and other navigation systems to provide real-time location data to fleet managers. This information is crucial for route optimization, monitoring vehicle usage, and ensuring driver accountability. Vehicle tracking can also enhance security measures by enabling the immediate location of a vehicle if it’s stolen or goes off-route.

Diagnostics: On the diagnostics front, telematics systems can read a vehicle’s OBD data to monitor its health and performance. This includes tracking engine hours, fuel use, battery life, and other critical indicators that can inform maintenance schedules and prevent breakdowns. By providing early warnings about potential vehicle issues, telematics systems allow fleet managers to address problems before they lead to costly downtime or repairs.

Telematics and Fuel Efficiency

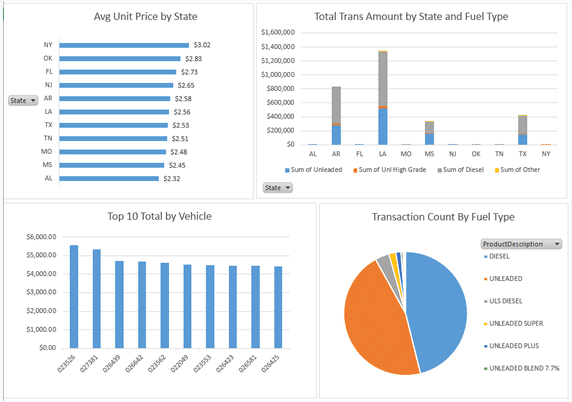

Telematics improves fuel efficiency by providing detailed insights into vehicle operations and driver behavior. Through data analysis, it identifies patterns and practices that lead to excessive fuel use. It can recommend actions such as better route management, smoother driving techniques, and timely vehicle maintenance. By addressing these factors, telematics helps in reducing unnecessary fuel consumption, thereby improving fuel efficiency.

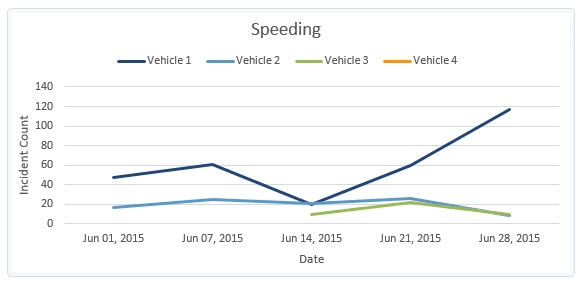

Monitoring Driver Behavior to Reduce Fuel Consumption

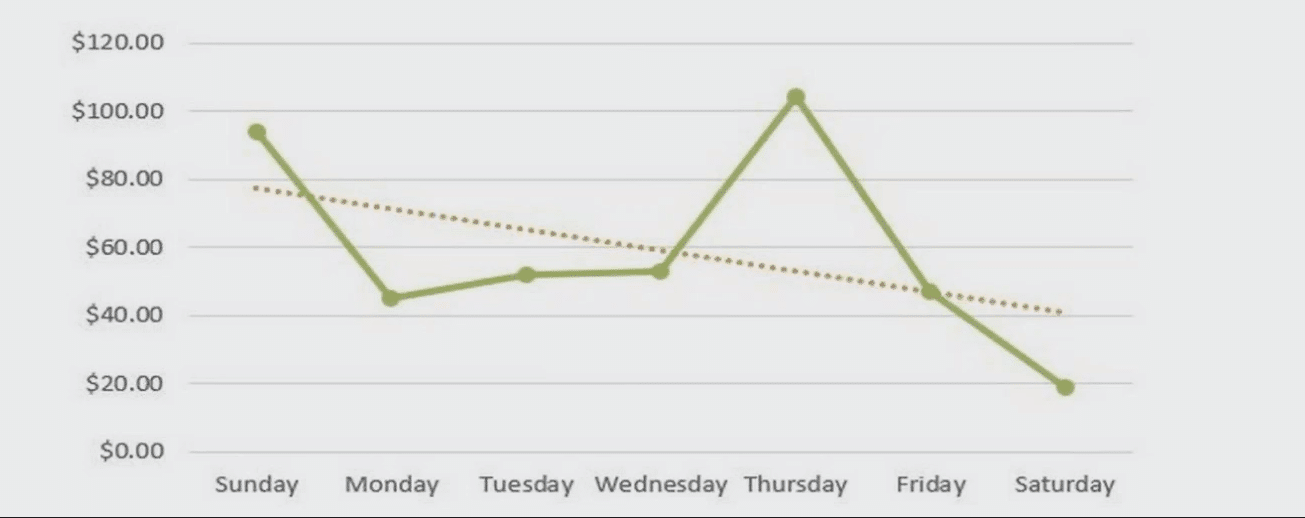

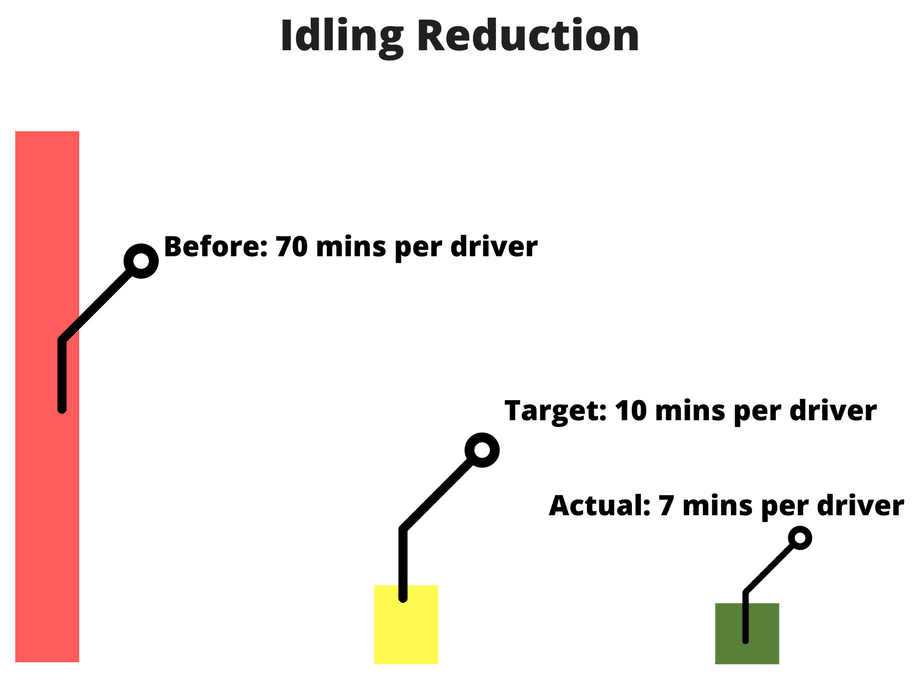

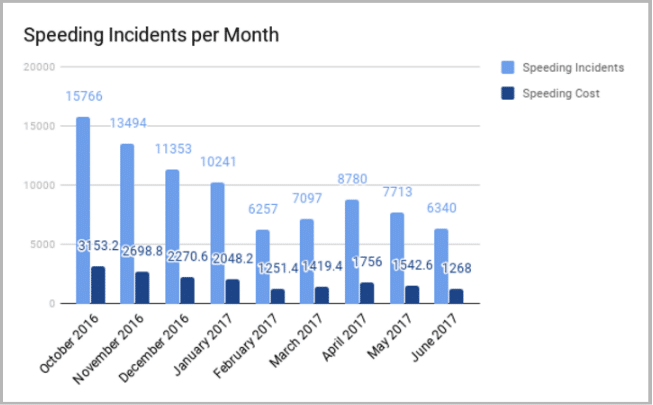

Driver behavior has a significant impact on fuel consumption. Telematics systems monitor behaviors such as speeding, idling, harsh acceleration, and braking, which are known to increase fuel usage. By analyzing this data, fleet managers can implement targeted driver training programs, promote more fuel-efficient driving habits, and set benchmarks for performance. This not only reduces fuel consumption but also promotes safer driving practices.

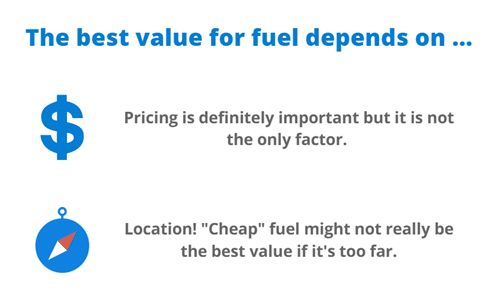

Route Optimization to Save Fuel

Route optimization is another way telematics promotes fuel efficiency. Telematics systems use GPS and real-time traffic data to determine the most efficient routes to a destination. Avoiding traffic congestion, reducing travel distances, and selecting routes with favorable conditions can significantly reduce fuel usage. This also leads to timely deliveries and improved customer satisfaction, as drivers avoid delays caused by traffic jams or construction.

Vehicle Maintenance Alerts to Prevent Fuel Wastage

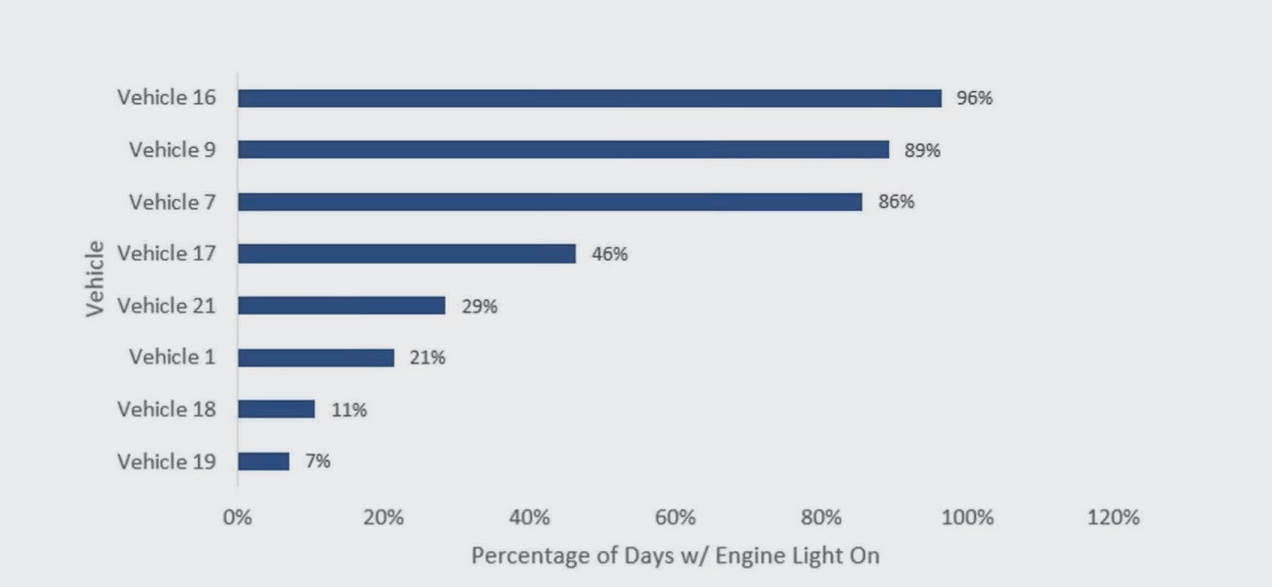

Proper vehicle maintenance is crucial for optimal fuel economy. Telematics systems provide maintenance alerts based on real-time vehicle diagnostics and usage patterns. Regular maintenance as per these alerts ensures that vehicles operate efficiently, with issues like under-inflated tires, dirty air filters, or misaligned wheels—which can all lead to increased fuel consumption—being addressed promptly. By preventing these issues from going unnoticed, telematics helps in maintaining the fuel efficiency of the fleet.

Case Studies

GCI Gravel Conveyor operates out of Indianapolis, with a fleet of 21 trucks. After implementing a telematics solution, GCI has reported annual savings of over $90,000 in fuel tax reporting alone. By using the telematics system to record when trucks are used off-road (and thus not subject to on-road diesel fuel taxes), they can accurately track and apply for fuel tax refunds. This precise tracking extends to other aspects of their business, enhancing overall operational efficiency.

In addition, the use of geofencing technology has enabled GCI to more accurately bill customers for time spent on a job site, with charges accruing by the minute once a truck enters a geofenced area. This not only ensures accurate billing but also contributes to an overall increase in operational efficiency and customer satisfaction.

This case study demonstrates the tangible benefits that telematics can bring to fleet operations, not only in terms of direct cost savings in fuel consumption but also in indirect cost savings through improved operational practices and more accurate billing and tax reporting.

Integrating Telematics into Fleet Operations

Integrating telematics into fleet operations can be a game-changer for improving fuel efficiency and reducing operational costs. However, successful integration requires careful planning, staff training, and the setting of clear objectives. Below is a structured approach to seamlessly incorporate telematics into existing fleet operations.

- Assessment: Conduct an in-depth review of current operations to pinpoint needs.

- Technology Selection: Select a telematics solution tailored to the fleet’s specific requirements.

- Installation: Implement the telematics devices across the fleet, ensuring proper setup.

- Integration: Seamlessly incorporate telematics data into existing management systems.

- Policy Development: Formulate guidelines for data handling, privacy, and usage.

Training Staff on Telematics Usage

- Technical Training: Offer comprehensive training for relevant personnel on system capabilities.

- Driver Orientation: Educate drivers on the benefits and operation of the telematics devices.

- Ongoing Support: Provide continuous support for any technical queries or issues.

Setting Goals and Benchmarks for Fuel Savings

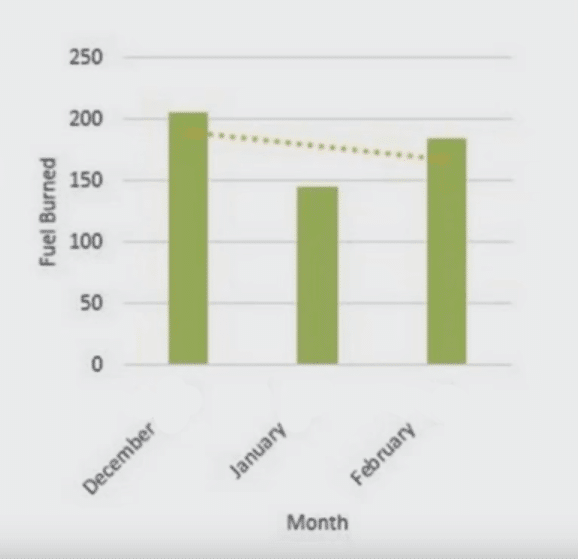

- Baseline Measurement: Determine the current fuel usage to establish a reference point.

- Target Setting: Define clear and attainable goals for reducing fuel consumption.

- Performance Monitoring: Regularly track progress using the telematics system.

- Feedback Loop: Review data periodically, give feedback to staff, and adjust goals as needed.

Challenges and Considerations

Telematics systems are powerful tools for enhancing fleet efficiency and safety, but deploying them can present challenges that must be thoughtfully addressed. Concerns about privacy, the costs associated with telematics solutions, and the balance between initial investment and long-term savings are among the top considerations for fleet managers.

Addressing Privacy Concerns

Implementing telematics requires handling sensitive data, which can raise privacy concerns among drivers. It’s essential to establish clear policies that define how data will be collected, used, and protected. Transparency with drivers and stakeholders about the intent and use of data is critical to fostering trust and ensuring compliance with privacy laws.

The Cost of Telematics Implementation

The initial cost of telematics devices and software can be a hurdle. It includes the expense of hardware, installation, training, and potential upgrades to existing systems. Fleet managers must consider these costs against the budget and look for solutions that offer the best return on investment.

Balancing Initial Investment with Long-Term Savings

The upfront investment in telematics technology must be justified by the long-term savings it can deliver. While telematics can reduce fuel costs, improve maintenance, and enhance efficiency, these savings may take time to realize. Managers need to calculate the expected return on investment and create a timeline for when savings will offset the initial costs.

Final Thoughts

Telematics has proven to be instrumental in reducing fuel consumption through efficient route planning, improved driver behavior, and timely vehicle maintenance.

If you’re ready to explore how telematics can benefit your fleet, contact a GoFleet expert today. Our consultants are equipped to tailor a telematics solution that aligns with your business goals and drives you towards a more efficient, cost-effective future.