It’s well known across the fleet management industry that preventative maintenance (PM) will reduce downtime and save you money, yet so many companies still fail to have one in place. Here’s a quick introduction to setting up a top-notch PM program for your fleet.

What’s Preventative Maintenance and Why’s It Important?

Preventative maintenance is regularly scheduled maintenance on a vehicle to reduce breakdowns. PM is done while the vehicle is still in working condition, in order to keep it running at optimal performance levels and greatly reduce downtime.

PM is important because it minimizes downtime and maximizes revenue.

If you don’t have a preventative maintenance program in place, you are putting your vehicles and drivers at a much higher risk of breakdowns and costly downtime. Preventative maintenance also helps keep your vehicles running in top shape, which can directly have an effect on the efficiency and fuel economy of your vehicles.

Why Do So Many People Fail to Perform Preventative Maintenance?

While preventative maintenance saves time and money in the long run, fleet managers and business owners often only look at the initial costs and time investment necessary — and do not look at the entire big picture. Implementing a preventative maintenance program may take some initial costs and dedicated time from your team up front, but the pay off in the long run is well worth it.

Preventative Maintenance Made Easier With Telematics

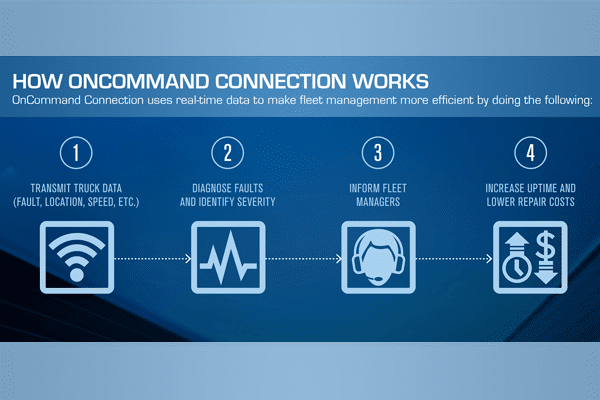

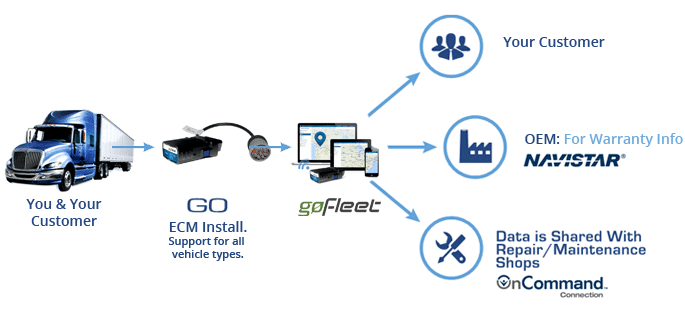

There are multiple maintenance management software systems out there on the market, but many are missing one critical aspect, which is the ability to actually communicate with the vehicles. When a maintenance management system can communicate with your vehicles, the entire process can almost be automatic, with very little room for human error.

That’s where telematics comes into play. By combining maintenance management software with vehicle engine data, such as odometer and engine faults, preventative maintenance can be triggered to schedule within the software automatically.

How to Set Up a Preventative Maintenance Plan Successfully

- Perform an inventory of all fleet vehicles. Review the maintenance records for each vehicle to determine regularly required maintenance activities and parts. Establish a list of priority vehicles.

- Set an annual budget for maintenance.

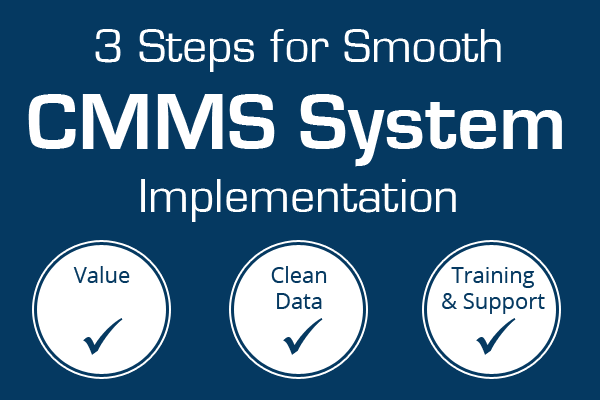

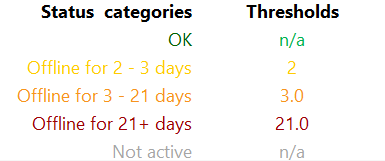

- Implement a maintenance management system to automate and streamline work orders, PM scheduling, inventory and parts management, purchasing, and reporting. By using an online maintenance assistant for reporting, you can measure and analyze key program metrics such as: closed work orders with all costs; work orders suggested vs. completion date; low stock report; and maintenance by type.

- Create a PM checklist & schedule. Be sure to consult the manufacturer’s recommended maintenance schedules for each vehicle to help establish appropriate frequencies. Implement a system for sending alerts when maintenance is due.

- Determine the best method for communicating maintenance plans and receiving reports and feedback, e.g. informal (emails, calls, weekly updates) or formal (monthly meetings with a structured agenda).

- Establish the method of record-keeping on ongoing maintenance activities. How will the information be reported and where will it be stored?

- Review and analyze the PM program regularly to ensure that it is meeting your budget and expectations. Look for areas of improvement where possible.