The growth of globalization and e-commerce has prompted the rising need for more efficient and cost-effective inventory management solutions to improve warehouses’ operational efficiency. Asset managers across industries have concluded that the warehouse information management system is an essential pillar to effectively facilitate large-scale warehousing tasks. In fact, it’s been noted that smart warehousing is an ongoing trend that needs to be monitored.

However, the COVID-19 pandemic has posed greater challenges to warehouse operations worldwide. This is because staffing issues and physical distancing rules make today’s warehouses hard to operate without adequate technologies and automation. The pandemic also has a trickle-down effect on the supply chains, which forces businesses to adopt innovative solutions to keep a close eye on inventory and stock.

In adapting and shifting to the “New Normal”, finding and implementing a smart warehousing solution is a primary task for asset managers. Bluetooth Low Energy (BLE) technology is the perfect solution to achieve the most efficient logistics operation possible and keep track of the asset movements.

We will show you why BLE has the leading edge over other solutions and how it can transform your businesses’ warehousing operations in the real-world.

What’s BLE?

BLE is a simple highly-automated wireless local data network that enables informational communications between assets. There is no barcode, no paperwork and no wire needed to operate the network. It’s as easy as attaching BLE beacons to the assets, plugging in readers to the power outlet and powering on a cloud database to see all the information.

The initial investment costs of a BLE system is very low, and the installation process is fast and simple. Best of all, because most smartphones have Bluetooth connectivity already, they can be used as a reader and mobile end device to receive and display information with compatible asset management applications installed.

This is extremely important for smart warehousing since the workforce is constantly moving between warehouse aisles and shelves. Having all the information they need in the palm of their hands is a huge productivity booster for all employees as they can clearly see, track and monitor all assets on the go.

Why Use BLE?

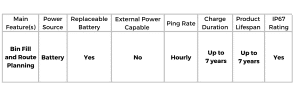

As the name suggests, low energy consumption is what makes BLE technology special. BLE beacons use low amounts of power on a battery that can last anywhere from one to five years. Because they are so reliable, it requires very little maintenance work to keep those beacons running.

Beacons will automatically alert the asset managers in advance before the battery runs out so managers can order a replacement battery or a new unit in time. The high versatility of BLE technologies means that asset managers can use them in a wide range of settings. As BLE beacons run on its own power and can function without a SIM card or mobile signal, they can be placed anywhere.

Some common placements of beacons are:

- Forklifts or other moving or stationary commodities

- Human assets

- Self-powered assets

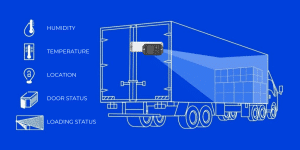

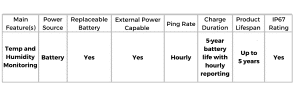

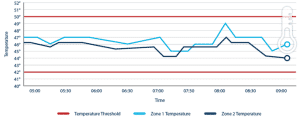

Product customization is one of the top considerations for asset managers when choosing tools and solution packages for their businesses. BLE solutions satisfy business needs by offering a wide range of unique customizations. It can track temperature and humidity, perfect for cold chain inventory management or temperature-sensitive commodities tracking. Customers can choose to pack in an accelerometer into the BLE beacons, which is essential to detect drop or article orientations for high-valued or fragile commodities. From the software end, asset managers can set geofencing boundaries, which provide enhanced safety protections for critical items – an alarm will be triggered if the item enters or exits virtual boundaries.

Additionally, the authentication feature can be built right into the BLE, allowing improvement to be made in the warehouse security management field. Many warehouses are high-traffic spots and supply chain integrity and security can be easily compromised if businesses do not value the importance of security. By implementing a BLE-based security network, warehouse managers can now keep the warehouse secure by only granting people wireless access to places where they need to enter. This could protect employees’ safety and deter theft and damages to the commodities.

How Does BLE Come Into Play With Smart Warehousing?

When it comes to a highly localized environment like a warehouse, we believe there are four essential aspects that managers should focus on when implementing smart warehousing management techniques. Directing the focus to these four aspects can enhance employee productivity and operational efficiency – and the BLE solution plays a big part in each of these areas.

-

Getting The Foundation Right

Creating the ideal and optimal warehouse space layout is a precondition of facilitating efficient asset management and inventory tracking. Warehouse asset managers need to identify current traffic bottlenecks in the warehouse and make every effort to reduce travel time between the commodities storage spaces and the fulfillment centre and optimize inventory placement. This analysis work could not be done without first learning the assets historical performance data and travel patterns.

Asset managers need a reliable tool that can be easily attached to each moving asset to collect vital information that helps them gain deeper insight into potential conflict points in the warehouse that may slow down the operations. Historical data is also crucial in assessing inventory placement and seeing what kinds of improvements can be made to optimize the pick-up efficiency.

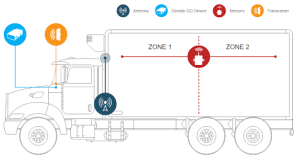

Defining zones and stocking rules can be an especially helpful strategy in warehouses that store multiple types of inventory with different handling and storage rules. For asset managers, you want to make sure that you are putting time-sensitive inventory and short-term storage items in an easily accessible location and place long-term non-perishable goods in the back of the warehouse. In any of these scenarios, the BLE-based inventory tracking system can help the asset manager monitor all the goods movements to make sure they are stored in the right location. This system can truly help warehouse facilities set themselves apart as a highly-efficient hub that can handle and store any kinds of goods.

-

Live Inventory Tracking

Forget about all the cumbersome manual entries work and complicated paperwork needed for inventory tracking and recording. The BLE-based warehouse management solution can record all the inventory changes and tag all received inventory. With the power of advanced computing, the system can automatically plan out the best location to store the inventory depending on the inventory types, as well as the fastest route to a destined storage zone.

Inventory counts are widely considered one of the most challenging tasks in large warehouses. The BLE system can handle it with ease as it provides real-time accurate inventory information and reports it to asset managers with an unparalleled level of detail and clarity. It streamlines and digitalizes the entire inventory tracking process and reduces the costs of paying dedicated personnel to count and record the inventory manually. With the proper configuration set up, the system can automatically alert asset managers if inventory is running low or the stock level is abnormal.

The BLE-based system can also assist asset managers in finding free storage spaces in the warehouse. A common scene in a warehouse setting is that staff are storing inventory in the closest shelves to the loading and unloading bays for convenient access, leaving many shelves at the back of the warehouse underutilized. The BLE system accurately calculates the warehouse spaces based on the real-time inventory count to provide warehouse managers with a complete picture of the warehouse’s available storage spaces. There is a very good chance that warehouse managers will find ways to make use of the underutilized storage spaces and discover new potentials to expand warehouse capacity.

-

Utilizing Equipment And Assets More Efficiently

Making the most out of material handling equipment and tools in the warehouse can significantly improve overall operational efficiency and reduce costs. Similar to tracking inventory, asset managers can attach BLE beacons to any kind of equipment and tools to track their usage.

The forklift is one of the essential pieces of equipment in the warehouse, and by attaching BLE beacons to the forklifts, asset managers can track their locations and collect travel patterns of these forklifts. By analyzing the equipment usage patterns, assets managers can identify idle assets and reduce equipment idle time.

It also helps asset managers optimize the storage location of equipment to make sure they are easily accessible by staff and workers. The BLE system presents a huge opportunity for creating an integrated operational platform that links equipment, personnel, assets, and inventory together and creates a streamlined warehouse workflow.

-

Unlocking The Power Of Artificial Intelligence And Big Data

Artificial intelligence and the adoption of big data analytics will have fundamental impacts on warehouse operations and completely reimagines what the BLE system can do.

By attaching BLE beacons on each moving asset, they can map out the entire warehouse path network and allow the system to utilize computational power and artificial intelligence to draw out the best routing for every trip. The system can predictively identify bottlenecks by analyzing historical trip data and patterns and reroute equipment operators to reach the destined zone. This could eliminate as many traffic conflict points as possible in the warehouse and put every vehicle and equipment on the most efficient route.

Another crucial improvement of the AI-powered BLE system is combining multiple work orders into one trip to reduce unnecessary trips. The system can smartly identify any work orders that can be done within one trip and assign the optimal routing to operators to collect all patches along the way.

With a BLE network in place, warehouse managers can observe a significant improvement in the facility’s capability to handle more orders because of a more streamlined inventory management solution that can automatically record every step of the inventory storage process. The data collected from equipment and inventory movement will be calculated and analyzed by the system to help warehouse managers identify equipment idle time, space availability, average travel time and a wide range of performance indicators. From there, warehouse managers can assess where there is room for further improvement and optimization.

BLE based inventory management and tracking solution is the future of smart warehousing management. Warehouse managers need a constant flow of information and data that is connected to equipment and inventory systems to effectively manage a constant flow of goods. Contact us to speak with a BLE solution expert to learn how we can leverage BLE technologies and create a customized solution package so you can achieve smart warehousing management.

Contributors:

Alan Zheng, Content Writer

David Herrington, Product Manager