When you think of electric vehicles (EVs), what immediately comes to mind? Very likely you’re thinking about those tiny little cars and even tinier parking spaces outfitted with charging stations. But did you know that modern EV’s come in all shapes and sizes? Auto companies are constantly coming up with innovative ways to “electrify” large trucks and other heavy-duty vehicles, and there’s never been a better time to plug in.

Many major auto manufacturers, including Ford and Rivian, are rolling out electric commercial vehicles, and because they’re only likely to become more common than less, there are a number of things to consider when deciding whether or not to make the switch from gas to electric trucks for your fleet.

EV or Gas-Powered?

There’s never been a better time than now to start thinking about adding EVs to your fleet. There are pros and cons to early adoption of electric trucks, including business needs, vehicle requirements and resources to support both EVs and gas-powered vehicles.

Pro #1: Saving Money

Compensation can be a big incentive for fleet managers who are on the fence about making the switch to electric vehicles. According to Environment Canada, the transportation, oil and gas sectors were the largest emission producers in Canada, accounting for 52% of total emissions in 2019.

The Canadian Government introduced the Green Freight Assessment Program (GFAP) in 2018, in order to help fleets reduce fuel costs and emissions over the next four years. The GFAP applies to medium and heavy duty vehicle fleets who are considering purchasing alternative fuel vehicles; those who invest in retrofit or low-emission vehicles can receive up to $100,000 from GFAP.

Pro #2: Cutting Costs

EVs are four times more efficient than internal combustion engines, which means you save money on fuel. Furthermore, electric vehicles have fewer equipment needs; they don’t require spark plugs or oil changes, which translates to less time and money spent on maintenance.

Pro #3: The future is electric

The future is electric, and battery intelligence optimization is a key element to unlocking its potential. Not only does the future of electric trucks speak to a more eco-friendly future, but it also has the capabilities for stronger, faster and tougher vehicles. As fleets look ahead, national policy is going to change around zero-emission targets. For example, the U.K. is introducing a ban on petrol and diesel cars in 2035. If you don’t want to be left behind, now might be the time to consider adopting EV vehicles into your fleet. Electric trucks might not yet have the capacity for long-distance travel, simply due to the shortage of EV charging stations, but in the meantime, EVs are a great choice for local routes, and can make a big impact with short-distance travel.

What to consider

Although EVs represent a roadmap to eco-conscious trucking and huge fuel savings, There are several hurdles that remain before their adoption is widespread.

#1: EVs Are Expensive

New technology is expensive. For example, the 2021 Rivian R1T, one of the first all-electric trucks to hit the market, starts at $69,000 US — more than double the price of a 2020 combustion-powered Ford 150.

#2: There’s Not A Lot Of Data — Yet

Currently, EVs are limited to specific applications that are well-suited to the technology; there will be many questions about their capabilities until such time as they can log significant travel time in real-world trucking operations.

#3 Range Anxiety

Route distance and road range can be an issue without infrastructure, leading to “range anxiety”; the fear that a vehicle won’t make it to its destination before getting to a charging station. The higher the speed, the more energy EVs require — most experts recommend that EV drivers keep their speed under 100 km to maintain battery life.

In addition, EVs don’t perform well in the cold. Using the vehicle’s heating system in cold weather can drain the battery, leaving its range cut by more than 40%. If your electric commercial truck is loaded up with cargo, you will now have to consider how the additional weight could affect power, which might require more EV charging stations along regular routes.

Vehicle manufacturers are still trying to figure out range solutions for longer trips, including larger batteries that may have capacity to hold more electricity. For example, Rivian announced vehicle-to-vehicle charging, meaning drivers can charge their EVs with another one’s leftover juice. Even further down the road, there’s a city in Sweden that will soon install real-life “electric roads” that allow you to charge your EV while you drive.

Considering EVs? Consider GoFleet

It’s important to know your company intrinsically; what makes it tick, its size, scope, purpose, key stakeholders, what kinds of routes your vehicles take, and what kind of vehicles you already have so you can determine what you need. Can your company afford to invest in a complete overhaul of a brand-new fleet of electric vehicles? Probably not. If you start to gradually import new EVs, will your existing combustion-engine fleet suffer? How gradually should new vehicles be incorporated? As you start the process of adding EVs to your roster, GoFleet can help you make the transition as seamless as possible.

Manage and Support your EV fleet

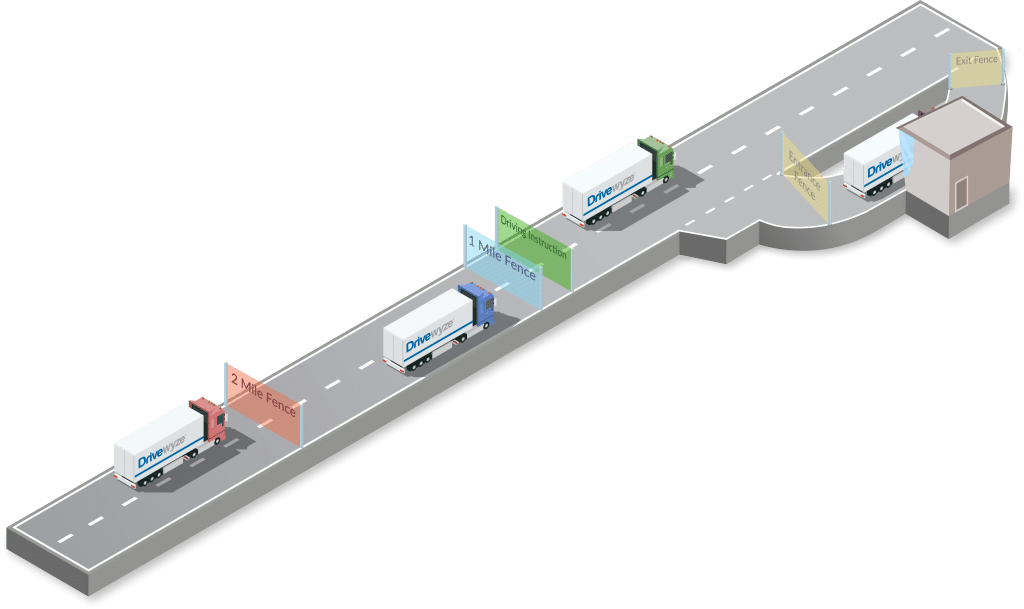

With GoFleet, fleet managers can stay on top of planning, scheduling, and completing service tasks with real-time updates and reporting. Review the fuel and EV energy usage for your fleet, allowing insights for electric range and performance of your vehicles. Reports could also be used to maximize and identify if any of your PHEVs are running solely on gas.

We’ll provide support across your entire EV fleet; If your drivers have smart devices, no additional hardware is required. Just install the gps tracking app on their phones and start running vehicles with more efficiency.

Visibility On Fuel And EV Energy Usage

We’ll supply a complete charging history of your EVs, showing you when and where the vehicles are charging, the length of time the vehicles were charging at a specific location, and how much of a charge they received. Our EV Charge Assurance provides a comprehensive view into the charging status of all your fleet’s electric vehicles.

In addition, you’ll receive alerts and notifications, such as when battery levels of a vehicle reach critical levels while on the road and the battery needs to be charged. Remind your drivers when it’s time to plug in and prioritize charging order for your vehicles

The GoFleet Solution

Although diesel will likely remain many fleets’ primary fuel for the immediate future, especially for longer, more complex routes, the introduction of EVs represent the industry’s first steps toward a future beyond the internal combustion engine and a massive industry shift.

There seems to be a fast and furious race to the finish line to see who can bring EVs to market first, whereas the focus should be on smart, scalable implementation. Regardless of whether you choose an EV or gas-powered fleet, GoFleet offers comprehensive solutions designed specifically for your business requirements. We’ll help you determine what to look for based on your fleet’s needs; whether you’re transitioning to an entirely electric fleet or plan to retain gas-powered vehicles as well. We’ll help you strategize and plan for your fleet’s future, all while saving you time, money and resources. Contact one of our specialists today!