Fleet telematics has become an essential technology in modern industries, transforming operations across various sectors. By combining GPS tracking, IoT connectivity, and data analytics, telematics provides real-time insights into vehicle locations, driver behaviors, and overall performance. This technology is crucial for improving efficiency, reducing costs, and enhancing productivity.

This post will explore how transportation companies can leverage telematics to optimize routes, ensure timely maintenance, and boost productivity, making it a vital tool for modern fleet management. We will also explore how telematics specifically benefits three critical industries: construction, waste management, and transportation.

Fleet Telematics in Construction

The construction industry is complex and dynamic, requiring efficient management of equipment, vehicles, and personnel. Telematics offers several advantages that streamline operations and enhance productivity.

- Equipment Utilization and Maintenance:

Telematics systems provide real-time data on equipment usage, location, and health. This information helps construction managers ensure that machinery is optimally utilized and maintained. Regular maintenance alerts prevent breakdowns and extend the lifespan of expensive equipment.

- Improved Safety:

Safety is paramount in construction. Telematics can monitor operator behavior, such as speeding or harsh braking, and provide feedback to improve safe driving practices. Additionally, geofencing technology ensures that equipment remains within designated areas, reducing the risk of theft and unauthorized use.

- Enhanced Project Management:

By tracking the location and status of vehicles and equipment, telematics helps in better project planning and execution. Managers can allocate resources more efficiently, track project progress in real-time, and adjust plans as needed to stay on schedule.

According to a report by Construction Executive, telematics can reduce equipment downtime by up to 30% and increase equipment utilization by 20% .

Fleet Telematics in Waste Management

Waste management operations involve complex logistics and the need for efficient routing and scheduling. Telematics provides significant benefits in this sector.

- Route Optimization:

Telematics systems analyze traffic patterns and suggest the most efficient routes for waste collection vehicles. This reduces travel time, fuel consumption, and carbon emissions. Efficient routing ensures timely waste collection, improving customer satisfaction. A study by the Environmental Protection Agency (EPA) highlighted that using telematics in waste management can lead to a 15% reduction in fuel consumption and a 10% increase in route efficiency (EPA).

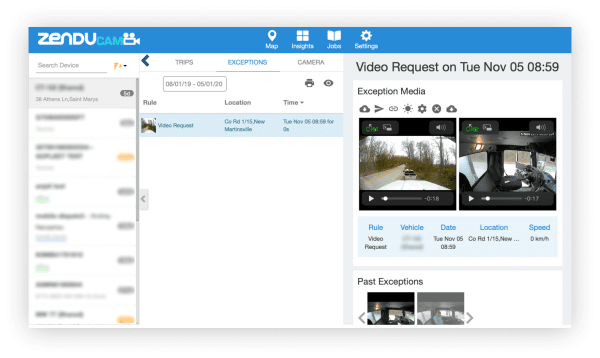

- Real-Time Monitoring:

Managers can monitor the location and status of waste collection vehicles in real-time. This visibility allows for quick adjustments to routes and schedules in response to traffic conditions or urgent requests, enhancing operational efficiency.

- Improved Compliance and Reporting:

Telematics helps waste management companies comply with environmental regulations by providing accurate data on waste collection and disposal. Automated reporting reduces administrative burdens and ensures that all regulatory requirements are met.

Fleet Telematics in Transportation

The transportation industry has been one of the earliest adopters of telematics, benefiting from improved fleet management and operational efficiency.

- Optimized Routes and Schedules:

Telematics enables transportation companies to optimize routes based on real-time traffic data. This reduces fuel consumption, minimizes delays, and ensures timely deliveries. Efficient scheduling also maximizes vehicle utilization and driver productivity.

- Enhanced Driver Safety and Satisfaction:

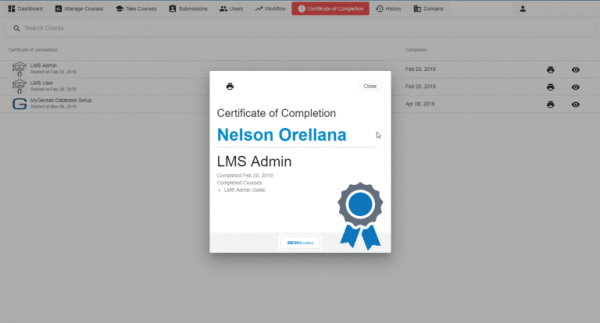

Telematics monitors driver behavior, providing feedback to improve safe driving practices. It also helps in optimizing driver schedules, reducing stress, and enhancing job satisfaction. Real-time updates and communication ensure drivers are well-informed and can adjust to changing conditions.

- Comprehensive Asset Management:

Transportation companies can track their vehicles and assets in real-time, ensuring they are used efficiently and are in good working condition. This reduces the risk of theft, loss, and unexpected breakdowns, improving overall fleet reliability. Research by Frost & Sullivan indicates that telematics can reduce transportation operating costs by up to 20% and improve on-time delivery rates by 15% (Frost & Sullivan).

What is the Impact on Driver Productivity and Satisfaction?

Optimizing schedules through telematics improves driver productivity by minimizing downtime and ensuring that routes are as efficient as possible. This not only enhances the number of deliveries or services completed but also reduces driver stress by avoiding traffic jams and delays.

Improved scheduling and real-time updates contribute to higher driver satisfaction, as drivers can complete their tasks more smoothly and effectively. This leads to a more motivated and productive workforce.

Final Thoughts

Telematics has proven to be a game-changer across various industries, including construction, waste management, and transportation. By providing real-time insights, optimizing routes and schedules, and enhancing safety and asset management, telematics significantly improves operational efficiency and productivity.

Embracing telematics is essential for future-proofing your operations, ensuring that your fleet remains competitive and efficient in an increasingly digital landscape.

Stay tuned for our next post, “How Fleet Telematics Improves Compliance,” where we will explore how telematics helps ensure adherence to regulatory standards and improves overall fleet compliance.